The light bulb conspiracy: Phoebus Cartel, 1924

By Aditya Chhatre

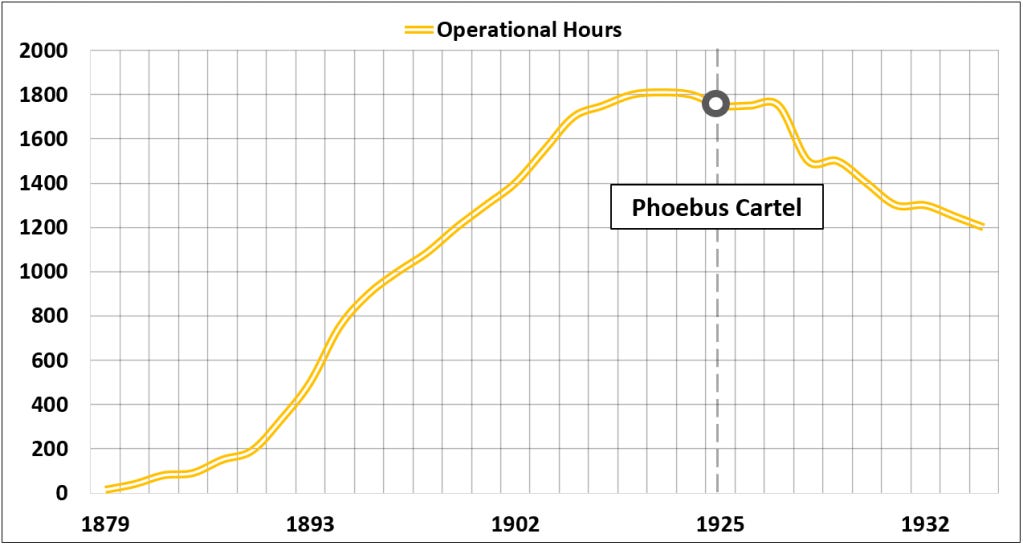

The light bulb at the fire station of East Avenue, Livermore, California has been operational since 1901. This incandescent light bulb has seen both the World Wars and is operational for 120 years now for more than 1 million hours. This 60W hand-made carbon filament light bulb was manufactured by Shelby Electric Company in Ohio. The decades of 1880 and 1890 were revolutionary for various incandescent light bulb designs and patents. Towards the start of 1920s the operational hours of these lights were over 2500 hours. Today, the average life of the similar incandescent light bulb is 1000 operational hours. How did we land up at such a design?

The invention of light bulbs dates back to 1878, the year when Thomas Edison had filed a patent with a vacuumed glass bulb with carbonized filament. This filament, when supplied with a voltage across it, after a threshold temperature, would emit light. After improvements in the filament material, the incandescent light bulb was in the market for use from 1880. The next technological development in the light bulb industry was from 1940-1980s where mercury-vapor lamp was used to produce visible light using fluorescence. These fluorescent tubes would excite the mercury when supplied with electric current, leading the inner phosphor coating to glow. Further at the end of the 20th century, a P-N junction-based light emitting diode (LED) technology was determined to be more efficient than the earlier ones. The LED light bulbs have been in the market since 2010. In 2020, the light bulb industry stands at a point of ‘socket-saturation’, a term used in lighting industry which describes the decline of incandescent bulbs and fluorescent bulbs as a whole, getting replaced by Light Emitting Diodes (LEDs). Light bulbs with LED technology, within just a decade, have growth to a market share of around 50%. At this point, it is interesting to look behind to a significant event in the evolution of the light bulbs. It is worth visiting this incident, which shows the pitfall when a better technology grows over the older one.

The Phoebus Cartel

In 1923, the sales of a major lightbulb manufacturing company based in Germany, OSRAM, dropped from 63 million to 28 million. The cause of the reduction in the growth was linked to the increase in the product life of the light bulbs which was about 2000 hours. A similar pattern was also felt by other bulb manufacturing companies. In 1924, the head of OSRAM was one of the first to propose a meet in the city of Geneva, Switzerland. Major lightbulb manufacturers met in Switzerland, including OSRAM, Philips, Compagnie des Lampes, and the General Electric. This body of bulb manufacturing companies was named as “Phoebus SA Industrial Company for the Development of Lighting”. Eventually this took form of a planned obsolescence by deciding to devalue the design of the light bulbs and limit them to 1000 operational hours. All light bulb manufacturers were obliged to send samples to the test facility at Switzerland. A deviation from the decided limit of 1000 hours resulted in heavy fees. This cartel achieved success within 15 years. The average operational life of the light bulbs was dropped from about 2500 hrs. in 1923 to 1200 hrs. in 1934. During the process, the increased volume reduced the manufacturing prices. Profits increased and as planned, the bulb manufacturing companies grew by 25% from 1926 to 1934.

Although new technologies were given pathways after the failure of the cartel in 1940 due to the tension between countries during World War II, even after almost a century, in 2021, the average life span of incandescent lamps still stands at 1000 hours.

Closely looking at the companies of the Phoebus Cartel, after the penetration of LEDs, most of them have moved away from the front-line light bulb manufacturing. Philips dropped off the Philips Lighting into a stand-alone company, forecasting the decline of the conventional lamps market. OSRAM and G.E. took the similar path of moving out by separating the lighting business into an independent company. Not that these companies have moved out completely; they have found other markets with LEDs such as ‘smart’ applications and street light with sensor applications. LED technology has risen from such times, which have a life of 10,000 to 50,000 operational hours. Principally, the point of concern is the lack of a business model of lasting products such as the centennial light bulb. The increased life of the products, surely creates a hiccup for the economic growth. Moreover, it could also possibly impact the society by lowering down the employment rates as there would be less need of factories and its workers. The choice is between an ever-growing economy and an everlasting product market. With the inclusion of LED technology, have we found the model to move from the short-lived to long-lasting products?

Course of action

In spite of the increased importance of concepts such as energy-efficiency, recyclability and biodegradability, the repetitive sales business model which became popular in the last decade of the 20th century still appears dominant today. However, we're seeing shift in trends for a few decades now with concepts such as circular economy emerging in the limelight. Many big businesses of today acknowledge the need of more sustainable economic models. This change would partly be driven by regulatory bodies which would support longer lifetime of the products. It would be difficult for the highly durable product market, having slower economic growth, to penetrate into the countries which use economic growth as their performance indicator. Tim Cooper, a sustainable-consumption researcher and a professor at Nottingham Trent University, suggests solutions for the systemic change for increasing the durability of the products and having economic stability:

Premiums: Premiums are currently used as a marketing technique for product placements and achieving higher profits. The higher premiums could be on the basis of uniqueness, limited edition products or could be on brand name. Premium products are believed to be having higher quality than a standard one. Based on products durability, an equivalent to the costs of conventional products, a premium can be charged to the products with higher life. The economic slowdown due to increased durability could be neutralized by such a strategy.

Second hand sector: A parallel business market shall be important to increase the use of products. A platform for second hand market will be beneficial to help for maximum circulation of products. This idea has started to take its shape, with big companies taking initiative. One of the such initiative is from Ikea, launching a program of taking back used furniture. The program is called ‘Buy back’, encouraging customers to hold up against aggressive consumption.

Rating schemes: Ecolabels such as Norway’s-Nordic Swan, EUs-Blue Angel have given a significant importance to the durability criteria for approval of a product. These schemes will make customers aware of products life, providing them information to compare products and make a better choice.

Tax: To incentivize products, the transferring the taxes of the labor segment to the use of energy and raw materials could aid the program, with the aim to have high prices for manufacturing new products and reduced cost for repair of the older ones. Also, a strategy with the sales tax could help similarly, by allocating a portion of the sales tax linked to the lifetime of the products, making short-lived products costly to buy.

From the learnings of the Phoebus Cartel, LEDs have overcome the limitation by increasing energy efficiency and lifetime of the light bulb. But it is still a long way for the markets to transform to an economy which could sustain products such as the centennial light bulb. Finally, it is a cultural shift of the mind-set from the newest and latest to the oldest and best.